Specifications:

| Log tilter combined with chain pusher |

| Log diameter, mm |

100-300 |

Log length, m |

2-6 |

| Length of rotating shafts, m |

2.6 |

Rotation drive power, kW |

0.75 |

| Chain pusher drive power, kW |

2.2 |

Log rotation speed, rpm |

0-10 (adjustable) |

| Chain pusher feed speed, m/min |

0-20 (adjustable) |

Weight, kg |

1050 |

| Dimensions LxWxH, m |

6.8x1.4x1.5 |

|

|

| Price: |

450,000r |

| Log separator |

| Log diameter, mm |

100-300 |

Length logs, m |

2-6 |

| Drive power, kW |

1.5 |

Lift speed, m/min |

11 |

| Weight, kg |

650 |

Dimensions LxWxH, m |

3.1x1.6x1.2 |

| Price: |

370,000 rubles |

| Drive overpass |

| Log length, m |

2-6 |

Receiving part length, m |

6.4 |

| Chain drive power, kW |

2.2 |

Chain speed, m/min |

8 |

| Weight, kg |

1350 |

Dimensions LxWxH, m |

6.4x3x1.4 |

| Price: |

580,000 rubles |

Price: 1,540,000 rubles

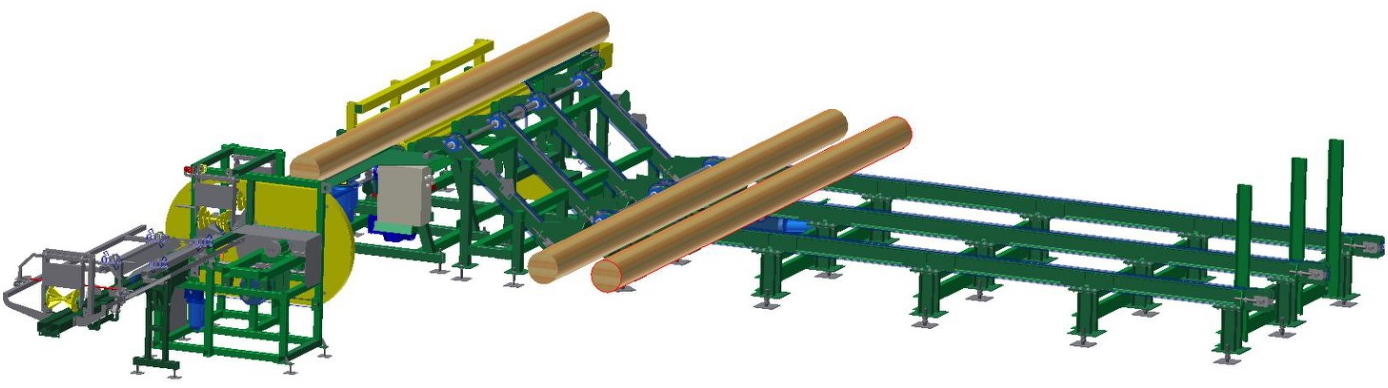

The automated log feeding system ASPB-300 is a comprehensive solution for the mechanization of positioning and flow feeding of logs into the UPT-250 small-timber processing machine. Structurally, the system consists of a drive overpass, a log disconnector and a log tilter with a combined chain pusher. All drives are controlled using a single joystick located directly on the UPT-250 machine control panel. The operator can visually monitor the process of log rotation/feeding using a special display that receives video from an HD camera.

Thanks to the automatic loading function, the operator does not need to monitor the process of log movement along the overpass and the operation of the log disconnector. The system itself will determine when the next log needs to be fed. The presence of a frequency converter allows smooth adjustment of the log rotation speed on the tilter and the speed of the pusher for feeding logs to the log hauler.

For ease of operation at the overpass itself, the operator can control all drives of the ASPB-300 system using a wireless radio remote control.

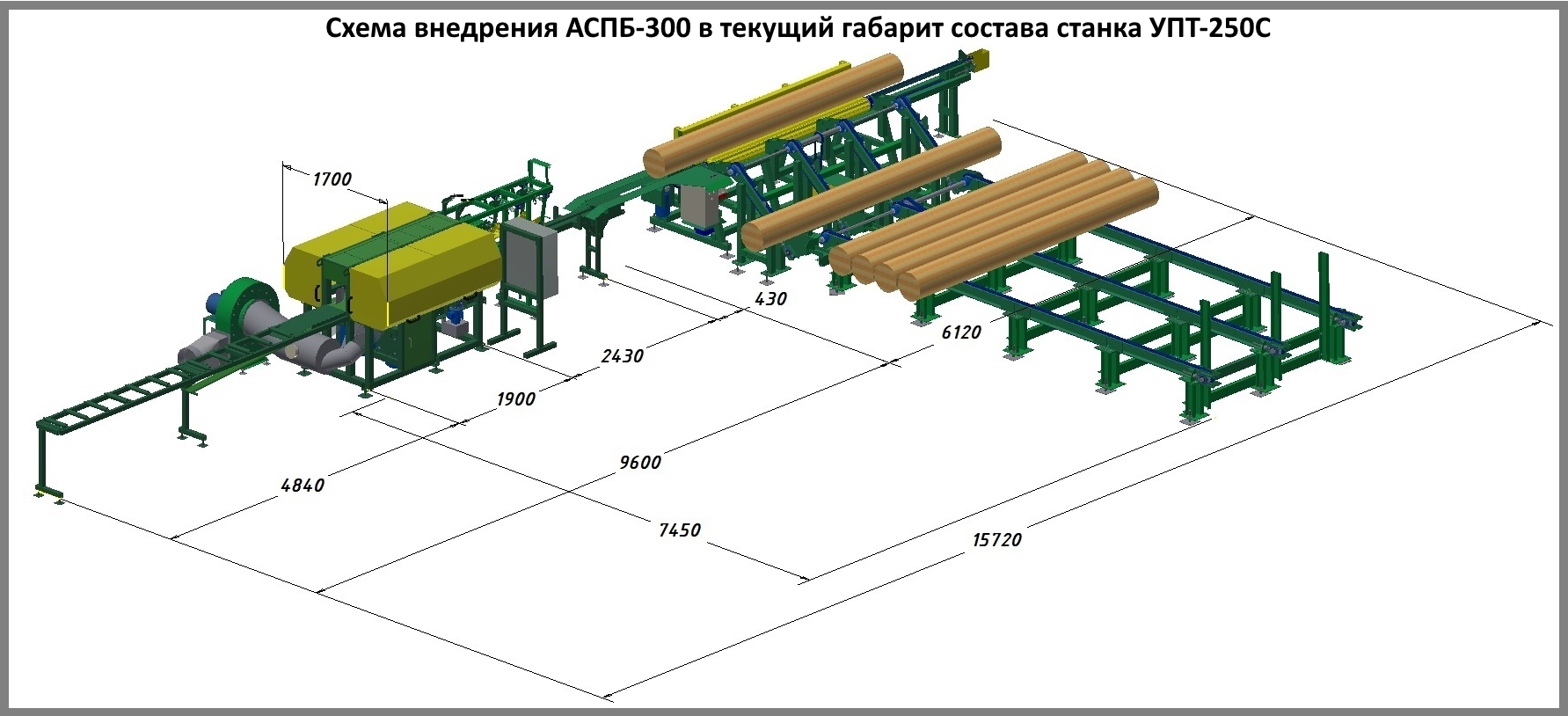

If necessary, ASPB-300 can be implemented into your current UPT-250M/S receiving table layout without increasing the length of the receiving table:

Using this system, you will be able to:

- fully mechanize the process of positioning and feeding logs into the UPT250 machine

- reduce to a minimum the distance between logs on the feeding table of the machine upt250, thereby achieving greater productivity

- reduce the number of workers to 2 people, since the entire system is controlled by the machine operator.

Distinctive features:

| Logs are fed end-to-end, reducing the distance between logs on the receiving table of the UPT-250 machine to a minimum – increasing the productivity of the machine. |

|

|

Thanks to the automatic loading function, the operator does not need to monitor the process of log movement along the overpass and the operation of the log disconnector. The system itself will determine when to feed the next log. |

| The presence of a frequency converter allows the operator to select the most convenient speed of turning (rotation) and feeding the log. |

|

|

Ergonomic and convenient control of the ASPB-300 system. One operator can control the machine and the log feeding system. |

| A high-resolution video camera coupled with a display located on the machine's control panel allows the operator to remotely control the process of positioning and feeding logs. |

|

|

With the help of a wireless radio remote control, you can control all ASPB-300 drives while being directly in the working area. |

| Modular design - allows you to assemble the system in any configuration, change the position and size of the receiving overpass. |

|

|

To prevent logs from tipping over, additional self-centering retaining rollers are installed on the receiving table of the UPT-250 machine. |

Complete set of the ASPB-300 system:

Drive overpass – 6.4 m

Log disconnector – 1 pc

Log tilter (rotator), combined with a chain pusher - 1 pc

Self-centering retaining rollers – 2 pcs

Integrated control system with a joystick - 1 pc

Display and HD camera - 1 pc

Radio control system - 1 pc

Video of operation:

If necessary, the ASPB-300 can be equipped with a log cutting unit. This system works as follows: on command from the joystick, the log, from the tilter

ASPB-300, moves through the saw unit of the end saw until it enters the sensor detection zone. Then the log is automatically cut to a pre-set size, which is determined by the position of the sensors. After that, the log is dropped onto the feed log conveyor (chain) of the machine

UPT-250S. Also, in addition to the main function of bucking logs, this system can be used to saw off logs for chopping firewood.

Video of the work: